Woven and non-woven polypropylene bags are 2 common fabrics used in producing shopping bags.

PP non-woven and PP woven are made from the same material: plastic resin. However the manufacturing process is different.

Non-woven shopping bags are not knit but bonded compare to woven bags. Indeed, PP woven bags include a weaving step, a manufacturing technique in which two sets of yarns or threads are interlaced at right angles to form a fabric or cloth.

Despite the manufacturing process, the 2 materials offer durable and reliable packing bags.

For other eco-friendly synthetic shopping bags options, please check out our other products:

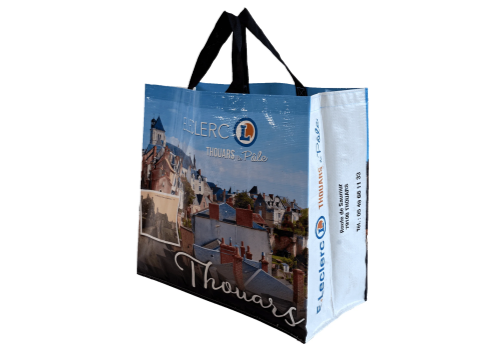

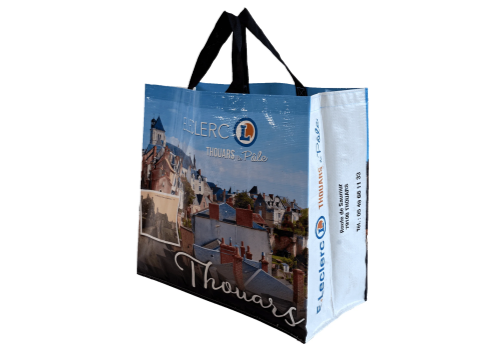

Woven polypropylene bags, also called PP woven bags, are one of the most popular bag types within the retail industry.

This wholesale shopping bag is lightweight, exceptionally strong, and perfect for heavy loads and long-term use. We even call them ‘bags for life’.

Besides its visible mesh, the PP woven bag can have an extra plastic layer with a BOPP lamination film. This laminated film makes the bag waterproof and easy to clean.

Woven polypropylene bags are an ideal alternative to plastic bags and are perfect for grocery retailers and promotional companies. 100% reusable and eco-friendly, these bags are easy to produce at a competitive price.

Material

Uses

Types

Options

Terms & Conditions

PP non-woven bags require a specific manufacturing step using air and heat to bond the plastic fibers. The composition is made from pressed polypropylene fibers which are shaped like honeycomb.

The main advantage of this technique is to produce a breathable and elegant bag with a super smooth outer surface.

An additional benefit of the non-woven bag is the choice to laminate, making it even stronger. This finish can be glossy or matt according to your needs, providing a perfectly smooth surface ready for printing your bespoke design and promoting your business.

We can help you personalize your bag with your logo or with highly personalized backgrounds.

Material

Usage

Standards

Options

Conditions